Which metal hose best

suits your application?

There are several variations of metal hoses, including corrugated and wound hoses. Corrugated metal hoses are the most common variant. The ridges and furrows of the metal hose make it possible to bend it. A corrugated metal hose allows you to transport liquids from A to B, as opposed to a wound hose, which must always be used in combination with a sealed hose to be able to transport liquids.

Corrugated metal hoses are available in various shapes and sizes. To find out which metal hose suits your application, you should consider two factors: the application and the maximum operating pressure. First of all, consider the application that the hose will be used for. This will determine which type of stainless steel hose you should choose.

When it is clear which type of hose is suitable, you should consider which hose can withstand the maximum operating pressure. The hose with a suitable maximum operating pressure will be the hose that best suits your application. Read on to find out which metal hose best suits your application.

Different areas of application

When choosing the right hose, it is important to consider the application that the hose will be used for. See below which hose is most appropriate for each area of application.

Maximum operating pressure of each stainless steel hose

As well as the application that the hose will be used for, it is also important to consider the maximum operating pressure. If a hose does not meet the maximum operating pressure, it is not advisable to use this hose for your application. We have made a list of measurements summarising the maximum operating pressures with which the above stainless steel hoses comply.

| Internal diameter of the hose (Nominal diameter [DN] in millimetres) |

Operating pressure in bar | |||||||

|---|---|---|---|---|---|---|---|---|

| Metalvisor series 4 | 161M | 161MXF | 161H | 162H | 161/2H | 162/2H | 162X | |

| 6 | - | - | - | - | - | - | - | 330 |

| 8 | 135 | 80 | 160 | - | - | - | - | 240 |

| 10 | 80 | 65 | 130 | - | - | - | - | 270 |

| 12 | 80 | 65 | 110 | 125 | 165 | - | - | 225 |

| 16 | - | 55 | 85 | 100 | 160 | 94 | 113 | 188 |

| 20 | 64 | 50 | 65 | 110 | 140 | 120 | 158 | - |

| 25 | 50 | 40 | 50 | 80 | 120 | 86 | 113 | - |

| 32 | 44 | 30 | 40 | 80 | 90 | 56 | 71 | - |

| 40 | 40 | 30 | 45 | 70 | 105 | 49 | 71 | - |

| 50 | 35 | 32 | 40 | 55 | 88 | 38 | 49 | - |

| 65 | 24 | 23 | 26 | 50 | 60 | 23 | 34 | - |

| 80 | 20 | 25 | 29 | 40 | 45 | 30 | 45 | - |

| 100 | 18 | 16 | 20 | 32 | 40 | 30 | 38 | - |

| 125 | 14 | 10 | 20 | 24 | 37 | - | - | - |

| 150 | 12.5 | 10 | 23 | 24 | 37 | - | - | - |

| 200 | 10 | 5 | 15 | 16 | 25 | - | - | - |

| 250 | - | 5 | - | 11 | 19 | - | - | - |

| 300 | - | 4 | - | 7 | 13 | - | - | - |

Temperature resistance

Stainless steel hoses are particularly appropriate for low temperatures, e.g. for transport of liquid nitrogen up to 196°C. Pressure resistance and flexibility do not decrease at these low temperatures. On the other hand, the maximum temperature is limited and is around 550°C for these hoses. Meanwhile, the pressure resistance decreases at temperatures above 50°C. Multiply the values displayed alongside the temperature by the operating pressure of your system. Stainless steel tubing is suitable for 100% vacuum applications and for pressures up to 330 bar, depending on the application. Stainless steel hoses are also the only hoses suitable for 100% vacuum applications.

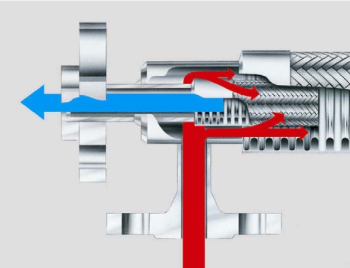

Hoses for high pressures, pressure surges, rhythmic volume flows or vibrations are highly susceptible to fatigue. A dual-layer metal hose has been specially developed for these applications: the

Hoses for high pressures, pressure surges, rhythmic volume flows or vibrations are highly susceptible to fatigue. A dual-layer metal hose has been specially developed for these applications: the  A hose with a more V-shaped corrugation profile than the above hoses has been developed specially for the transport of liquid foodstuffs. This makes the hose easy to clean and means that no medium remains in the ridges. This profile does make the hose less flexible. One condition is that the hose must be welded according to DIN2827. Aseptic fittings compliant with DIN11864 are welded onto the pipe by welding robots to ensure a full aseptic connection between the hose and the link. The type of hose that best suits these requirements is the

A hose with a more V-shaped corrugation profile than the above hoses has been developed specially for the transport of liquid foodstuffs. This makes the hose easy to clean and means that no medium remains in the ridges. This profile does make the hose less flexible. One condition is that the hose must be welded according to DIN2827. Aseptic fittings compliant with DIN11864 are welded onto the pipe by welding robots to ensure a full aseptic connection between the hose and the link. The type of hose that best suits these requirements is the  If the medium must not be allowed to cool during transport, you should choose a type

If the medium must not be allowed to cool during transport, you should choose a type